What is predictive maintenance for electric motors?

Predictive maintenance programs use condition-monitoring tools and testing systems within the motor to track the equipment’s performance. Sensors installed in the electric motors stream real-time data into a computerized maintenance management system (CMMS) and identify areas that need attention.

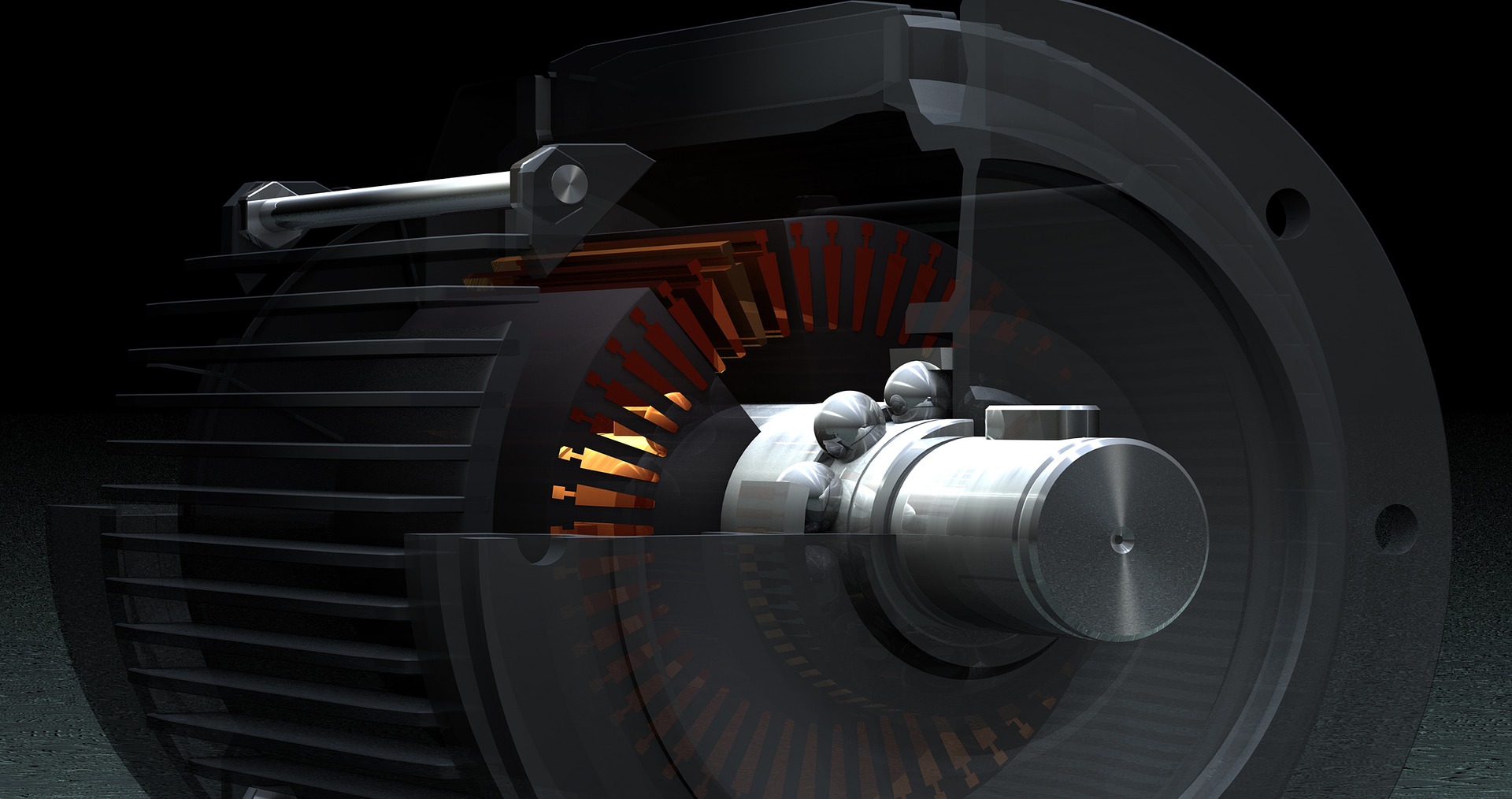

Monitoring devices on electric motor

Monitoring devices on electric motor

Monitoring the motor while it’s in operation assists the detection of potential defects, allowing repairs and the replacement of components, such as motor controls, bearings, and stator windings, before failure occurs. This strategy helps to avert both unnecessary and unplanned downtime and increases productivity.

Here are five reasons why predictive maintenance should be performed on electric motors:

1. Cost Benefits due to Increased Motor Life

Replacing parts at scheduled times, even if they don’t quite need replacing yet, increases a company’s cost in spare parts and supplies. Alternatively, only replacing the components after they’ve failed and the machine no longer runs is even more expensive. The most cost-effective method of maintenance is to replace parts as needed, not before or after. With predictive maintenance techniques, upkeep and part replacement take place just before equipment failure is likely to occur. That way, it saves you from the expense of unnecessary maintenance and preventable breakdowns.

Using predictive maintenance programs for your electric motors also saves money by minimizing the cost of spare parts and supplies. Items are only ordered and replaced when they need to be, and ongoing repairs as required to prevent breakdowns, prolonging the life of the machinery.

As a result, companies using predictive maintenance over preventative or reactive, achieve a 70-75% decrease in breakdowns and 25-30% reduction in maintenance costs. These programs have also been shown to produce a tenfold increase in return on investment!

2. Reduced Downtime

When predictive maintenance programs are in place, maintenance is only performed when required. Compared to other techniques, such as preventative or reactive (run to failure), this dramatically reduces the downtime for maintenance. In fact, reports show that compared to other techniques, predictive maintenance results in a 35-45% reduction in downtime.

Continuous monitoring and analysis of conditions in the machine identify which components are faulty or will soon need replacing, allowing your maintenance personnel to schedule repairs as they are required. By streaming real-time data into a computerized maintenance management system (CMMS), predictive maintenance programs can be up to four times more effective at reducing downtime than reactive maintenance.

The most common (and effective) monitoring methods are:

- Infrared thermography – detects excessive heat in bearings and circuitry

- Vibration analysis – detects misalignment in rotating components

- Ultrasound monitoring – detects inaudible leaks or friction

- Lubrication testing – for detecting metal particles in the oil, which indicates grinding

3. Better Technical Support

The sensors that are installed in your machinery to allow for predictive maintenance stream real-time data about the conditions of the motor and its components to a CMMS. This system can be connected to an external control unit, allowing you to monitor the operating conditions of critical motors and their components.

This accessibility to tools and technology that can provide accurate analysis and data collection allows for better technical support. The ability to monitor conditions remotely also helps you and your technicians to stay on top of issues before they happen.

4. Encourages a Proactive Workforce

Successful processes in a predictive maintenance program are driven by the people, not just the equipment. People processes outline the way that your staff work with each other, the data, and the machinery.

Having data from the installed sensors integrated into a CMMS allows personnel to see when problems are forming and address them as needed. In this way, employees become a proactive part of the process of preventing electric motor failure.

5. Better Knowledge of Machine’s Working

Many companies across a variety of industries use machinery in their production or processes. Most only understand what the machines do, or how they speed up production and streamline operations within the business, but not how the machinery itself works. Parts get replaced according to how long it’s been since the last service, not based on what the motor actually needs.

Working with a predictive maintenance program gives you a better understanding of the way the electric motor works, how the different parts interact, and which sections need maintenance the most often. Its methods of detecting operating conditions while the motor is under full load provide valuable insight into the state of your machinery. Over time, the data will allow you to consistently document failures and estimated lifetimes of the motor’s components.

They rely on maintenance companies and personnel to tell them what kind of maintenance they need, how often they need it, and which parts need to be replaced.

There You Have It

As you can see, there are many benefits to predictive maintenance techniques, cutting costs, and downtime, while boosting technical support and familiarity with your company’s machinery. Here at SLS, we are dedicated to bringing Singapore the best in electric motor testing and predictive maintenance programs. Remember, the purpose of predictive maintenance programs is to determine the best time to perform repairs and replace components. The goal is to keep maintenance frequency as low as possible, while keeping mechanical reliability as high as possible, saving you time and money.

Ready to Start Your Predictive Maintenance Programs?

Our SLSPro engineers provide predictive maintenance programs and services for your electric motor testing in Singapore. If you’re looking for cost-effective electric motor testing in Singapore, contact us now and our SLSPro engineers will be able to help you set up a predictive maintenance program for your machinery.