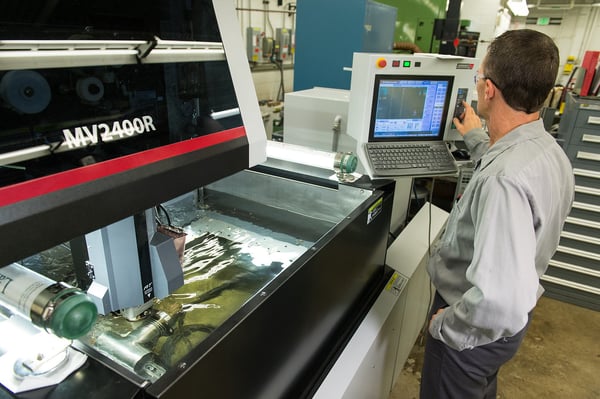

EDM or spark machining may use brass wires or electrodes for electrical discharge machining. This process creates sparks that are emitted by electrodes or wires. It erodes some of the materials to make specific parts of machinery, cars, and appliances.

Die sinker EDM has many functions. They can mirror electrode shapes and make them into a desired accessory, and they can make the wires’ starting holes for EDM. The sinker EDM machining is a process of fabrication that removes some materials from the workpiece. The removal involves a series of discharges involving current and electrode with a dielectric liquid separating the voltage.

One of the electors is called a tool, while the other is known as the workpiece. This process will depend on the two not getting in contact with each other. When the operators increase the voltage between the two, the electric field’s intensity adds as well. This will result in a liquid dielectric breakdown where the materials are removed from the electrodes.

Once the voltage has stopped running, the solid particles are carried away while the dielectric’s insulation properties are restored. When a new liquid is added into the enter-electrode, flushing can occur. After the current flow, voltages may be restored to their original state before they have broken down. A newer dielectric liquid is needed to repeat the same cycle.

A Look into the History of this Process

N. I. and B. R. Lazarenko were two Russian scientists who were tasked to do an investigation that involves tungsten erosion because of sparks. They failed on their task to prevent total erosion. However, they discovered that the task involved a more controlled environment in tungsten electrical contacts if they are immersed with dielectric fluid. You can know more about the dielectric fluid when you click here.

This is the start of the invention of the EDM machining used to work with tungsten and other materials that prove difficult to work with. The first inventions were called R-C-types or resistor-capacitor circuits, and they are used to charge the electrodes.

At the same time, American teams like Jack Beaver, Harold Stark, Victor Harding, and others developed a new kind of machining to remove aluminum casting taps and broken drills. The initial construction of the devices was for etching tools, but they didn’t achieve much success. More powerful units were combined with fluid replacement and acted with automatic spark repetition.\

Uses of EDM Machining

EDM has many uses, including the burning of electrically-conductive metals. The process is done without the added physical stress of other machining types. This will improve the shaping and cutting procedures and precisely get what the manufacturers want in their materials. Some of their typical applications include the following:

1) Die Making

Tools like dies shape or cut the materials and make them into solid products. EDMs are utilized to create the tools regardless of the shapes and sizes that they need are common enough.

2) Making of Molds

Molds are places where liquids and other substances are shaped into their desired form. The depth and dimension of the mold can be perfectly achieved with the help of EDM.

3) Small Hole Drills

Without the help of EDM, drilling and creating small holes can be a challenging process. This method’s ability to recreate smaller shapes makes it an ideal way of drilling smaller sizes that can be achieved in no time.

Generalities to Know

EDM is a method that uses hard materials and others that can be difficult to drill holes into using the traditional ways. The machine works with materials that can conduct electricity, although others can discover that they can achieve the work using ceramics.

In pre-hardened steel, an electrical discharge machining process can make intricate patterns and contours without softening the material. Other alloys are applicable in this machinery like Inconel, Hastelloy, titanium, and Inconel. You can learn more about the Hastelloy brand here: https://en.wikipedia.org/wiki/Haynes_International.

This is the non-conventional group of machining that is commonly grouped into laser cutting, water jet cutting, and electrochemical machining. The conventional ones are considered drilling, milling, turning, and grinding that uses mechanical forces to shape the metals.

EDM is one of the essentials in the manufacturing industry that can produce various workpieces in large volumes. You can know more about how the metals are submerged into an insulation liquid on many websites and blogs on the internet.