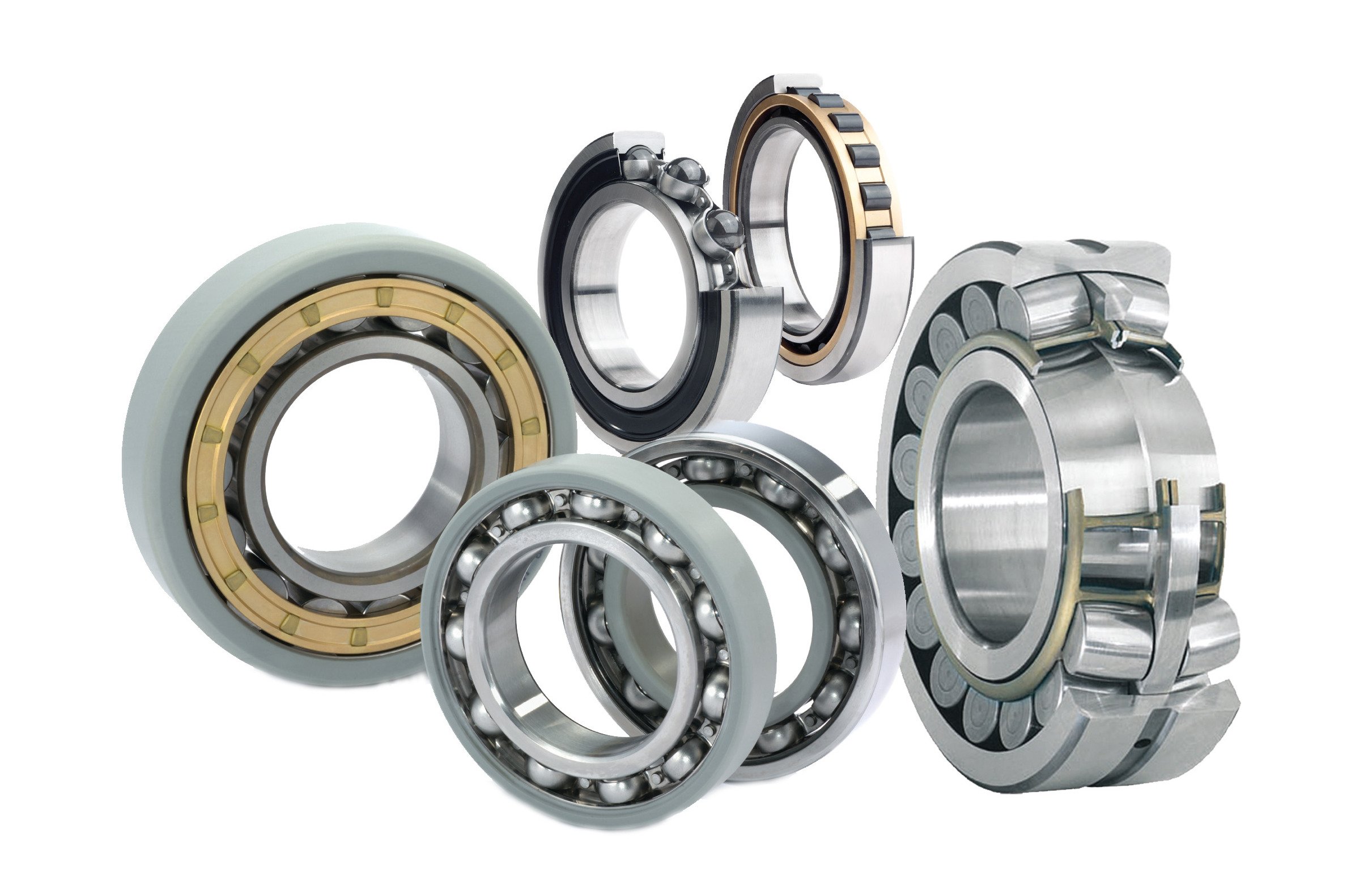

Finding the right bearing for industrial applications is vital to ensuring high-level production, low-level downtime, secure maintenance programs and a long-factory life.

After all, almost every moving part in a machine, be it a car or the factory floor, needs to have fitted roller bearings and ball bearings in order to reduce friction, smoothen the motion, reduce costs with automation and better the longevity of the moving parts as a whole.

Being the selected bearing supplier in Singapore, SLS Bearings has everything you need to know about finding the right bearing components and materials to fit your machine.

The Development of Bearings Over the Years

Surprisingly, the concept of friction-reducing movement through the use of a ‘bearing’ came about far earlier than the wheel. In fact, it was almost a predecessor to the wheel.

There are cave paintings around the world showing wooden logs and fallen trees being used to transport heavy objects from A to B. As wooden logs roll over the ground, heavy objects were pushed over a succession of logs that would continuously be placed in front of each other until the journey’s end.

This was such a common practice for centuries and was even used in the innovations of the Ancient Egyptians. Using wooden bearings was done alongside various liquids to use as lubricants, before new metals such as zinc and bronze were introduced but were all insufficient in strength and capability as a bearing.

However, when the industrial age began, it was a time of metal forming processes where steel became a popular industrial material. And, in 1794, a man named Philip Vaughan patented the design similar to the ball bearing we know today.

Read more: 4 Interesting Facts About Bearings

The Importance of Choosing the Right Bearing Components and Materials

In an industrial setting, we all know how crucial it is to find the right components of the puzzle to reduce costs and increase output.

And it’s no different when it comes to sourcing from the bearing supplier in Singapore; making considerations for industrial use, choosing the right bearing components and materials will be a frictionless process.

Without due attention to ball bearing and roller bearing fit, there’s a change of seeing reduced efficiency, needless downtime, increased maintenance attention, friction wear on adjacent components and even equipment seizures.

Read more: Why Are Ball Bearings Used in Machines?

To avoid seeing rolling contact fatigue (RCF) and damage from incorrect bearing components and materials, the following considerations should be met:

A bearing must be able to handle the anticipated pressure and weight of the radial load, axial load and combined load in order to function efficiently and to the intended lifespan.

2. Speed

Machines operating at high speeds must have speed-dedicated bearings able to withstand the extra force added to the bearing in motion. For example, the ability to withstand minor misalignment while in rotation.

3. Temperature

A ball bearing needs to be able to have the right space to allow for thermal expansion and resulting friction heat. Non-conformal contact between the ball bearing and the attachment can increase the friction and thermal conductivity between components.

4. Sealing

The sealing of the bearing is crucial to maintaining lubrication levels and decreasing debris infiltration within the bearing components and materials. In a high debris producing plant, a shield sealing is recommended.

5. Maintenance

The right ball bearing or roller bearing will have the maintenance requirements that match or exceed the maintenance program in operation. By balancing the cost of the bearing with the life performance, it can be critical in avoiding expensive downtime. Here are 8 essential tips of bearing maintenance to prevent premature failure and enhance the performance of your bearings.

You can read more about finding the right consistent and actionable maintenance program to prolong motor lifespan and prevent failure.

The Different Types of Bearing Materials

With the industrial revolution bringing the steel bearing onto the scene, there have since been considerable developments with various materials.

Typically, steel is used as the main roller bearing and ball bearing material for both the rolling component and the rings. However, some industrial instances call for other qualities such as greater resistance to corrosion, porosity, cost savings, seizure resistance, lightweight materials and high durability.

Therefore, the below bearing materials are chosen depending on the mechanical processes:

1. Carbon Steel Bearings

Also called ‘commercial grade’, carbon steel is not stainless steel in that it instead features a carbon element of up to 2.1% in weight. The higher the carbon content, the stronger the bearing. With this, however, it becomes less ductile, has a lower melting point and can’t operate large loads or high speeds.

The benefits to using carbon steel bearings include being the cheapest bearing material for use as well as its hardness.

This type of bearing made with carbon is commonly seen in rolling draws, locks, bikes, roller skates and shopping carts.

2. Chrome Steel Bearings

Another type of steel bearings is the chrome steel bearing and it is one of the most prominent types of bearing components and materials due to the affordable costs, high hardness level and quieter operating volume. Despite what the name might suggest, a chrome steel bearing has a low chromium level within the steel compound.

With this, the benefits of using a chrome steel bearing ends with the high-hardness, high-load capacity, low decibel, affordable cost and wide accessibility. However, it requires maintenance of lubrication and is not resistant to corrosion or chemicals.

As one of the most commonly sourced bearing from the bearing supplier in Singapore and around the world, it has a wide range of industry applications. For example, vibrating motor systems, food processing machines and linear motion components.

3. Stainless Steel Bearings

The final steel material used to create industry-suitable bearings is stainless steel. The composition has a lower percentage of carbon than carbon steel bearings and a higher chromium quantity than chrome steel bearings.

A stainless steel bearing is highly effective, precise, strong, durable, resistant to corrosion, chemical resistant, softer and temperature flexible than most other bearing types. The only negative aspects would be the heavier composition, need for lubrication and higher costs.

With this, the stainless steel bearing can be used in a range of industrial applications including those that are temperature sensitive. Examples include food processing, manufacturing, metal plating, instrumentation, high humidity and highly chemical areas.

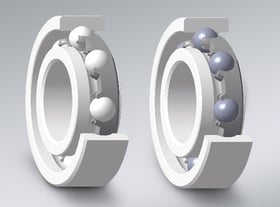

4. Ceramic Bearings

Ceramic bearings are manufactured to produce a highly non-corrosive and durable bearing with two rings of ceramic and a fluorine resin retainer. This material is chosen over stainless steel and its variances due to the non-magnetic requirements of the machinery.

With this, the benefits of using a ceramic ball bearing of Singapore include it being high in hardness, anti-corrosive, durable, lightweight, high-temperature resistant, low in density and low in maintenance due to not requiring lubrication.

The industry applications for a ceramic ball bearing are often within aircrafts, in the dental profession and in food processing machines.

5. Polymer Plastic Bearings

There are also many non-metallic materials used to manufacture ball and roller bearings due to lightweight qualities among others. Plastics and polymers used throughout the bearing industry include:

- Nylon

- Silicone Nitrate

- Phenolic

- Teflon (PTFE)

- Nitrile Rubber

With their porous material, polymer plastic bearings often have high temperature ranges and naturally low-friction properties meaning no lubrication is needed. Other benefits to using polymer plastic bearings include the resistance to corrosion, chemicals and rust as well as a lightweight body with high strength used for a range of industry machines.

The polymer plastic bearing is often used within electrical switch gears, water turbines, ship propeller shafts, household appliances, filming gear, instruments, textiles, factory floor applications and more.

6. Hybrid Bearings

Lastly, hybrid bearings are manufactured with best practice in mind. Using high radial and axial strength of steel for the rings and bearing grade silicone nitrate to manufacture the rolling elements, it provides electrical insulation.

With this, hybrid bearing types feature the benefits of high wear resistance, varied industry application scenarios, higher speed capabilities than most and non-conductive components for temperature rises or RCF.

High-level research and science machines such as cryogenic chambers, aerospace engineering and medical equipment make use of the hybrid bearing components and materials.

Choosing the Right Bearing Material for Your Equipment

As the leading bearing supplier in Singapore, we provide an array of bearings products and our team of experienced engineers are here to assist you with recommendations for the best type of bearings used on your equipment or your specific applications. To find out more about exactly which of the bearing materials are best for your machinery, get in touch with the SLS Bearings team below.

**All images were derived from SKF.com and NSK.com.