It will always be an annoyance to try replacing something without knowing exact models needed for purchase. This is especially true with flexible belts in transmission when there’s the need for a specific V-Belt.

Of course, this can happen for multiple reasons; if the V-Belt warps, if the writing is no longer present or if the belt snaps.

We have got you covered. In this blog, we’ll introduce types and subtypes that V-Belt manufacturers have to offer before explaining how to identify the V-Belt needed.

Types of V-Belt

There are three types of V-Belts available through a V-Belt manufacturer: the classical, fractional horsepower and narrow wedge.

Each type uses their own belt-code to describe the thickness and length of the belt. Each code is rated for their ability to hold certain loads, so it’s important to understand the differences and find which V-Belt manufacturer type would be best suited for you.

1. Classical

This is the most common V-Belt and is very durable in poorly operational machines such as old motors.

These belts have a high load range working from less than 1 horsepower up to 500 horsepower, and is the only belt operational at fractional horsepower rate and above 1 horsepower

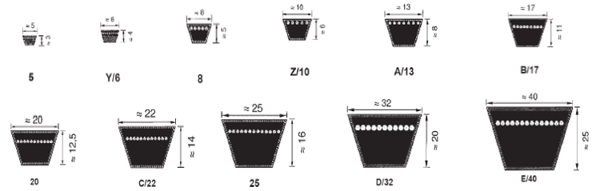

A V-Belt manufacturer will define the size and shape of the V-Belt by referring to its code; letters A-E describe measurements of the cross-section and then the size of the belt required in inches. For example; a Dunlop standard motorcycle would use an A48.

2. Fractional Horsepower

This belt only operates at a horsepower of less than one. Therefore, it is useful for light loads and slower transmissions. They are often found within washing machines or fans and should never be used for heavy-duty machinery as they will snap and cause damage to the overall system.

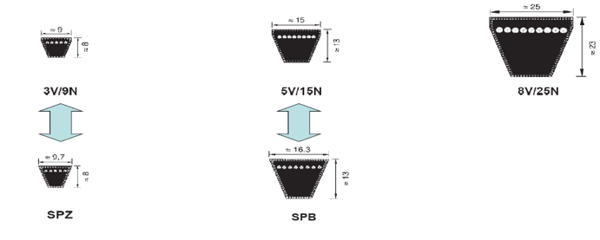

Unlike the classical V-Belts, the fractional horsepower (FHP) belts use size prefixes ranging from 3V to 8V.

3. Narrow Wedge

The narrow wedge V-Belt has a slightly different shape; it’s height to width ratio is larger and the ‘V’ shape is more defined.

The narrow wedge V-Belt takes higher speeds and heavier loads than the classical and fractional horsepower v-belts; from 1 horsepower, up to 1000 horsepower.

Benefits of Using the V-Belt Over Alternatives

Alternative belts such as timing belts have teeth that apply constant contact to a specific area of a rotational cog.

The V-Belt, on the other hand, is (mainly) smooth to offer movement which is necessary when a transmission speed requires an increase or reduction. As the belt moves, traction causes the cogs to adjust to the speed required, making it safer in many industrial, motor and home appliances.

Here are the benefits of using the V-Belt over its alternatives:

- They require no lubrication

- They are very quiet

- They do not transfer vibrations

- They don not require installation of tooth-drive sprockets

- They are very easy to maintain and replace

- They resist environmental pollutants

What are the Primary Applications?

V-Belts either transmit power between rotors or speed-up/slow-down a transmission. They are used industrially and in homes but are mainly found within the motor industry. This is because of car and motorcycle requirements to transmit power from the engine to the wheels.

In motorcycles, a V-Belt is used as the primary drive-belt and can last up to 100,000 miles if maintained correctly. While sometimes, a motorcycle will use alternative belts such as chains or toothed belts made by a timing belt manufacturer, newer bikes will feature the V-Belt. This is because of ease and other benefits mentioned above.

On the other hand, there’s cars. In cars, V-Belts are used as a transmission tool between many different components. And, when not using a serpentine belt, there will be multiple V-Belts overlapping in the same rotary course. The belts connect engine-force to ancillary components such as the hydraulic pump for power steering.

How Can I Identify the Correct V-Belt?

Now you know the functions of the V-Belts while recognizing the need for one, it’s time to know how to correctly identify which V-Belt you need for your rotary power transmission when the belt is broken or no longer labeled.

1. Identify the Cross Section

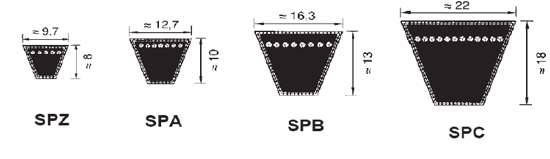

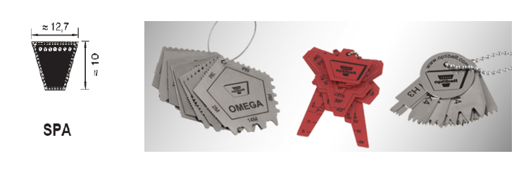

V-Belt cross sections can be identified by their top width and depth dimensions. For example, a V-Belt with a top width of 12.7mm and a height of 10mm is a “SPA” belt. Alternatively, you can also use V-Belt and Ribbed belt sheave measurement tools provide a quick and easy way to quickly identify the correct profile or power transmission drive wear problem.

2. Establish if the V-Belt is Wrapped or Notched Style

V-Belts have smooth and notched surfaces. Unlike the timing belts, the notches are not like teeth and unlike chains, the cogs cannot go inside the belt. The notches merely provide further traction.

When you identify if the belt has notches, this will change the code you need to identify the new belt. A belt with notches will have an added ‘X’ in the identifier code. For example. If you need a V-Belt in size C but it requires notches, the prefix would change to CX.

3. Find the Length of the V-Belt

You can use our Optibelt Measuring Gauge for measuring inner lengths of V-Belts, timing belts and ribbed V-Belts. (Measurement range: 500 –3550 mm (Li) inside length)

Alternatively, if you have the original belt to hand, the length needed for the new belt can be easy to find. Simply do this by using a measuring tape to know the outside length of the belt. Subsequently, we will refer to the Optibelt Conversion Factor Table to find out the calculation for datum length. You can find out how to measure V-Belt in this blog.

There You Have It

We hope that this quick guide provides you with the understanding on how to identify the correct V-Belt type. As an authorized distributor of Optibelt, we provide a wide range of V-Belts that suits your needs. If have any questions or would like to know more about how to select the right type of V-Belt for your operation, get in touch with us below:

**All images were derived from Optibelt