O-rings are one of the most common seals used in equipment design because they are reliable and have simple mounting requirement. While these type of seals are often inexpensive, their failure can lead to significant amount of loss in production, downtime and maintenance costs.

If you are new to O-Rings, We strongly recommend that you read our O-Ring introduction blog to have a deeper understanding before delving into this topic.

Therefore, it is important to look out for early warning signs and understand the various types of common O-Ring failure to prevent any unwanted damage or cost during critical operation.

Here are 5 of the most common reasons why O-Ring fails, the type of typical damage and the recommended corrective actions:

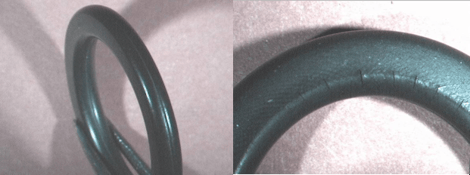

1. Extrusion/Nibbling

Description

O-Ring surface peeled off or nibbled off at the opposite side of pressure, often only on part the circumference.

Cause:

- Material overflow on one side, also temporary

- High/pulsating pressure (Hardware expands or contracts)

- Sharp groove edges

- Radial clearance is too large

.jpg?width=235&name=extrusion%201%20editpaint%20(2).jpg) Example: O-Ring surface nibbled off

Example: O-Ring surface nibbled off

Corrective Actions:

- Back-up rings

- Different seal profile

- Decrease clearance

- High-modulus/hardness elastomer

- Proper gland design

2. Twisting/Spiraling

Description

Spiral marks or tears in the O-Ring surface.

Cause

- Irregular rolling/sliding of the O-Ring because of

- High surface roughness due to missing or wrong lubricant

- Out-of-round hardware

- Mounting error

Example: Spiral marks on O-Ring surface

Corrective Actions

- Careful installation

- Other seal profile

- Change hardware or working conditions

3. Permanent Distortion

Description

Distorted O-Ring, usually flattened on one side or both sides.

Cause

- Inadequate material quality

- Insufficient state of curing

- Contact with incompatible media/thermal overload

- Wrong groove lay-out

Example: (Left) Obvious flattened O-Ring on both sides, axial, material thermal overcharged

(Right) O-Ring with cracks

Corrective Action

- Correct material selection (medium, compression set)

- Right groove lay-out

- Reduction of working temperature

4. Ozone Cracking

Description

Cracks vertical to the direction of tension (stretched O-Rings) and shows signs of premature ageing.

Cause

- Stretching, time and temperature

- High ozone concentration

.jpg?width=235&name=ozone%20cracking%20after%20editjpeg%20(2).jpg)

Example: Stretched O-Ring

Corrective Action

- Select ozone resistant materials

- Change of storage conditions

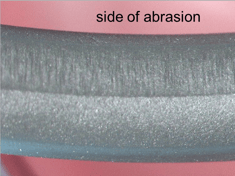

5. Abrasion

Description

Flattening on one side of the O-Ring cross section and the area of abrasion is smooth and shiny with loose particles.

Cause

- Wrong surface roughness

- Abrasive media

- Insufficient lubrication

- High, pulsating pressure with static use

- Dynamic motion

- Poor elastomer surface finish

Example: Abrasion area appears to be smooth and shiny

Example: Abrasion area appears to be smooth and shiny

Corrective Action

- Improve surface roughness

- Reduced squeeze or friction

- Avoid system contamination

- Consider internally lubed elastomers

- Eliminate abrasive components

Interested in knowing more about O-Rings?

At SLS, we have a team of product experts who are here to help you with your O-ring needs. If you would like to know more about O-rings or have any related questions, please reach out to us by clicking on the button below:

**All images were derived from NOK Freudenberg