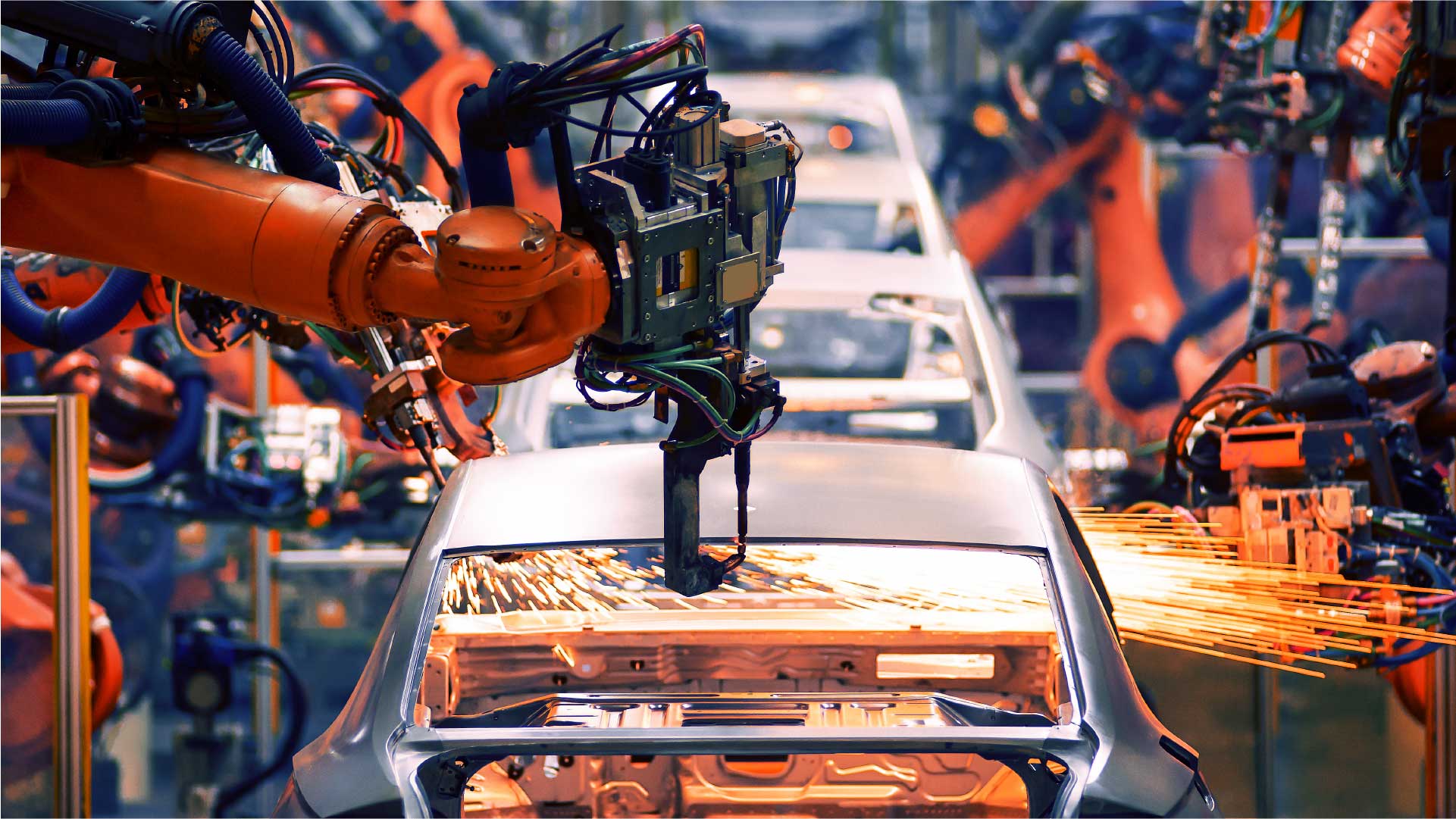

Smarter, more flexible and more functional, Industry 4.0 enabled automation is more accessible than you think

Around the world, factories are betting on the potential of Industry 4.0 and the Industrial Internet of Things to unlock a new wave of productivity, profitability and growth.

Industry 4.0 makes it cheaper and easier for companies to introduce new, digitally enabled approaches improving the performance and flexibility of the machines they already use and automating a wider range of tasks.

More, and better automation provides a combination of benefits for manufacturers:

- Reduce operating and labour costs,

- Improve productivity, quality

- Enhance safety

But the benefits don't stop there. If an organisation chooses the right technology approach, it can continue to capture additional value over the long term, connecting and integrating its automation systems into wider industry 4.0 networks and applications.

One of the most common building blocks of manufacturing automation is the requirement for linear motion. Linear actuators are used in countless industrial applications to transport, locate and position products, components and tools.

Electromechanical linear actuator benefits for future automation

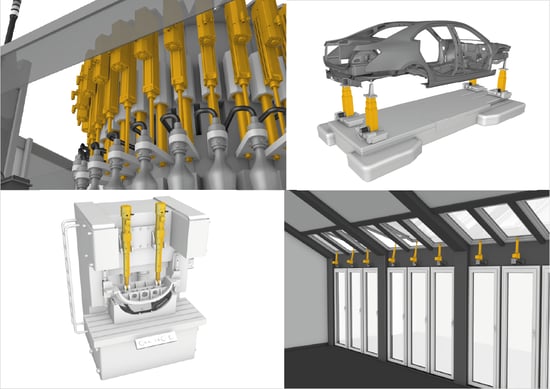

As we move into the industry 4.0 world, many manufacturers and machine designers are finding that electromechanical actuators provide a better fit for both their current and future automation needs. They are available in a wide range of standard designs, and in modular formats that allow power, speed and precision to be tailored for almost any conceivable application.

Electromechanical actuators can be found in various applications such as filling and labeling devices (top left),

automated guided vehicles (top right), servo presses (bottom left) and window openers (bottom right)

1) Less Hassle

Fluid power requires elaborate, dedicated infrastructure. Pneumatic systems need many components, including hoses, pumps, valves. Hydraulic systems require a fluid reservoir, pumps, motors, release valves, heat exchangers, along with noise-reduction equipment. An electromechanical actuator, by contrast, only needs a few cables to transmit power and control systems.

That simplicity leads to a smaller overall footprint and simple mechanical layout, reducing the overall design, installation and commissioning time required for an automation project.

2) Simple Integration

Electromechanical actuators are easy to integrate. With fewer components to consider, electromechanical systems can be used to add additional motion axes in tight spaces or onto existing machines. Control systems integration is straightforward too, with simple interfaces to all the major industrial network protocols.

3) Complete Control

In fluid power systems, precise control of the speed and position of the actuator can be difficult or impossible to achieve while electromechanical actuators provide complete controllability of the system, high levels of repeatability, as well as higher stiffness.

4) Better Efficiency

The electromechanical approach to linear motion can deliver significant total cost of ownership benefits over the full lifecycle of an automation system. While actuators contain high-precision components, the critical parts are well protected from damage and contamination, leading to a long, and predictable, working life.

An electromechanical actuator transforms 80 percent of the power it consumes into useful work, That’s around twice the efficiency of a hydraulic system, and more than ten times better than a typical compressed air installation.

The Smart Choice: Electromechnical Linear Actuators

New digital technologies are upgrading the intelligence, responsiveness and flexibility of manufacturing processes. But the manufacturing world is physical as well as digital; the next generation of production machines will need muscles to match their brainpower. When it comes to linear motion applications, electromechanical actuators are proving to be the smartest choice.

Interested to know more about Linear Actuators?

Hold the key to the future and if you would like to find out more about how linear actuators can fit your automation needs, please get in touch with us below:

Ewellix is a global innovator and manufacturer of Linear Motion and Actuation solutions used in industrial automation, medical applications, mobile machinery and distribution. Formerly part of SKF Group, the Ewellix Group consists of 16 sales units and nine factories. External net sales are approximately 2.3 SEK billion and we employ around 1400 people. Ewellix is headquartered in Gothenburg, Sweden and is owned by Triton Partners.

Ewellix is a global innovator and manufacturer of Linear Motion and Actuation solutions used in industrial automation, medical applications, mobile machinery and distribution. Formerly part of SKF Group, the Ewellix Group consists of 16 sales units and nine factories. External net sales are approximately 2.3 SEK billion and we employ around 1400 people. Ewellix is headquartered in Gothenburg, Sweden and is owned by Triton Partners.

**All images were derived from Ewellix