Company

Yenn Dar Pte Ltd started its business activities in commercial building services (piping, air-conditioning & mechanical ventilation systems), process piping for chemical plants and steel structural works. They have since then expanded their scope into contracting services and providing FAB space management and drafting services, engineering support and contracting works in ferrous and non-ferrous piping, thermoplastic piping, steel structure beams and supports, as well as Electrical & Control Design, Engineering and Installation.

The Problem

Centrifugal Pump Bearing Application

Customer bought the SKF Oil Seal TC55x80X13 Viton and encountered a lubricant leakage in the pump only after 3 months of operation.

How SLS Created Advantage

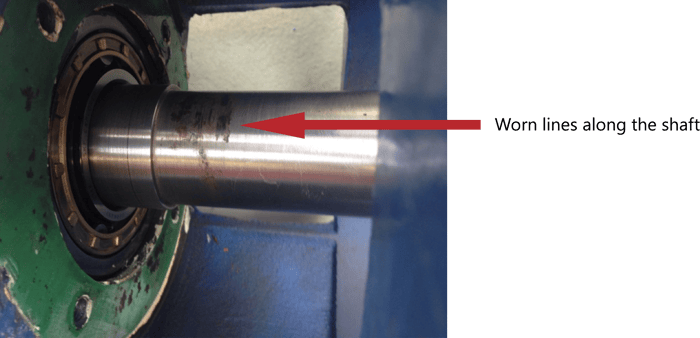

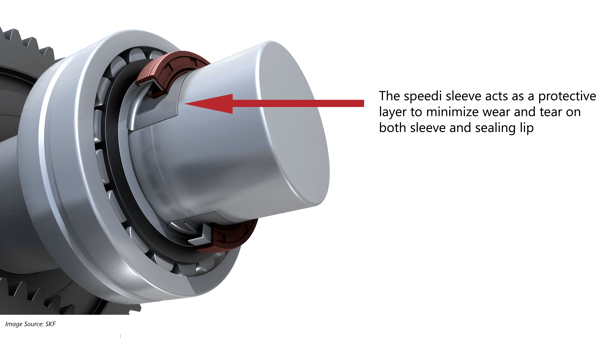

Our team received customer’s request and promptly conducted an inspection on the application specification and tested the compatibility of the seal to this application. After careful evaluation, we determined that the oil seal was compatible with the application. In order to find the root of the problem, we performed a different check-up on its shaft condition, only to discover worn lines on the shaft, which contributed to the leakage of lubrication. As our customer had to meet urgent demands on that day, we recommended the SKF Speedi Sleeve. The Speedi Sleeve offers a cost-effective sealing solution when machine shaft surface have been damaged or worn during operation.

By SKF: The Speedi Sleeve uses a proprietary stainless steel material and manufacturing process, resulting in an optimized seal counter-face surface that minimizes wear on both sleeve and sealing lip. The proprietary material provides increased strength and excellent ductility of the sleeves. Imperceptible lubricant pockets enable the lubricant to reside on the sleeve and thereby prevent dry running of the sealing lip that otherwise can create excessive wear.

SKF Speedi Sleeve

Result

Through diligence and expertise in product knowledge, the SLS team was able to come up with a quick and effective solution to help our customer in the most critical time. The shaft was up and running within minutes, at a fraction of the cost of traditional reworking.

Delivering cost-effective solution to you whenever you need it

We care for our customers and recognize the challenges that you may face during your business operation. Here at SLS, our team are committed to delivering the best solution for your operation, and the optimization of your system and processes.

Facing a similar problem?

We are here to help. Talk to one of our experienced engineers to arrange for a consultation:

.jpg?width=737&name=hockcheong%20(2).jpg)