In Part 2 of our focus on Oil Seals, we examine common reasons for industrial oil seal failure and what can be done to address such problems.

Industrial Oil Seals are used in various industrial applications. These seals help increase machine efficiency and productivity and help reduce maintenance time and costs. Depending on the type of seal, some can handle a wide temperature range.and have special properties such as resistance to abrasives, chemically compatible and having low wear. Oil Seals can be used in various industries such as chemical processing, oil and gas, pharmaceutical, general industry, hydrocarbon processing, and so on.

Like any other mechanical component, Industrial Oil Seals can also be susceptible to failure. Some of the top reasons that can lead to Industrial Oil Seal failure and how these can be solved are as follows:

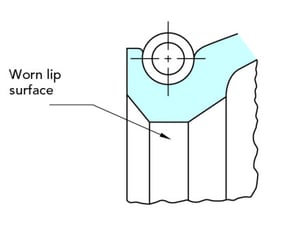

The lip edge is severely worn, and the worn surface appears dull and rough.

Image by NOK.

Image by NOK.

Cause: Insufficient Lubrication

This is due to insufficient lubrication, which has led to increased friction and as a result, abnormally high wear. The amount of lubricant applied was below the specified level and therefore, did not reach the sealing lip.

Solution: Add lubricant up to the specified level before operating again.

2. Failure mode: Oil seal deformation

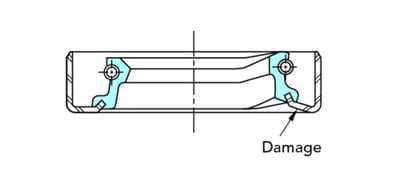

The oil seal is damaged causing lip deformation.

Image by NOK.

Image by NOK.

Cause: Inappropriate assembly

This problem can occur when the inside diameter of the Oil Seal is too small. The oil seal may also have been deformed due to an inappropriate assembly jig or wrong installation tools being used.

Solution: To fix this issue, use the right tools and improve the assembly jig.

3. Failure mode: Lip hardening

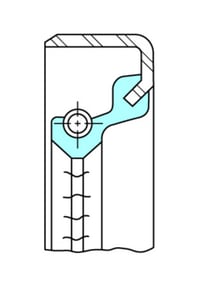

The lip wear band is smooth and glossy. The entire sealing lip is hardened and cracks appear.

Image by NOK.

Image by NOK.

Cause: Abnormally high temperature

This problem occurred because the oil temperature near the sealing lip exceeded the heat-resistance limits of the rubber.

Another reason could be that the oil temperature exceeded the design temperature limits due to application condition changes.

Solution: Investigate the cause of failure and take the necessary measures to prevent future temperature spikes.

If the oil temperature exceeds the design temperature limits, choose a seal with a better heat-resistant lip material, for example, changing from nitrile rubber (NBR) to acrylic rubber (ACM), or acrylic rubber (ACM) to fluorocarbon rubber (FKM).

Do take note that a change in lip material also means the oil resistance will be changed.

4. Failure mode: Collapse or tearing of sealing lip

The sealing lip gets scraped or collapsed or the flexible part is torn.

Cause: Improper shaft chamfer or incorrect tools being used during assembly. Another reason for this can be high pressure directed at the flexible part.

Solution: To fix this problem, chamfer the shaft to the correct size, choose the correct assembly tool, and apply grease to the chamfered area before assembly. Also, choose an oil seal suitable in handling high pressures. Proper material handling is also key.

5. Failure mode: Garter spring disconnected

One of the most critical problems that have been reported with regards to Industrial Oil Seals is that the garter springs out of the groove.

Cause: This can occur because 1) the chamfer does not have the correct angle or 2) it can be due to incorrect assembly with grooves that are not deep enough.

Solution: If your problem was because of 1), you may use a mounting sleeve, or properly chamfer the shaft. Apply grease to the chamfered area before assembly. For failure mode 2), you need to assembly the unit correctly by aligning the shaft and housing bore. If required, choose another design or use a spring with a smaller diameter.

Want to Learn More About Oil Seal?

SLS distributes a wide range of oil seals for a variety of industries. Our sealing solutions are specially tailored to your industry. Our engineers have expertise in recommending seals for the petrochemical, oil and gas, and manufacturing industries, among others. We partner with a range of brands like NOK, Garlock and Economos to provide our customers with the best selection available.