Back in the days, pneumatics have for some considerable time been used for carrying out the simplest mechanical tasks. However in more recent times it has played a more important role in the development of pneumatic technology for applications such as robotic and automation.

But before we delve into pneumatic technology, some of you might be wondering.. what exactly is pneumatic? How does a pneumatic system work? And where can we use pneumatics? Without further ado, let us get down to it.

What is Pneumatics?

As we all know, there are different sources of energy such as wind, solar, hydroelectric energy and the likes. As for pneumatic, it is the use of compressed air to transmit force and energy. Pneumatics have built-in air storage and rely on the pressure that ensues from putting the air within an enclosed space.

| Important to note: |

| Compressed air needs to be processed before it can be used. While we only need the force itself, air can become contaminated with dust particles, water vapor or other risk elements. These can cause friction within the pneumatic parts. |

What is a Pneumatic System?

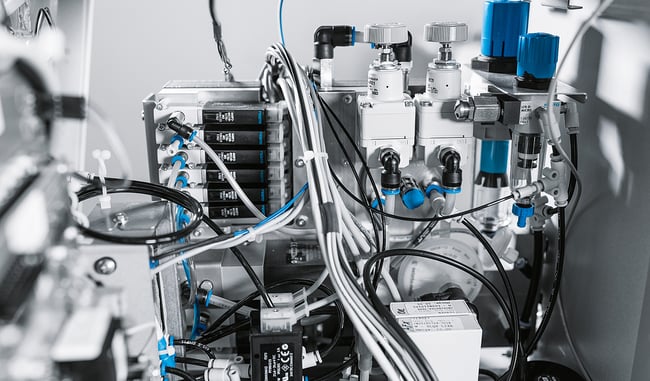

A pneumatic system is a system that uses compressed air to carry out work. They capture air, transport it around a circuit, and accomplish designated tasks with the generated energy. These are present in both manual and automated machines, and within the industrial sector such as construction and mining. In short, pneumatic systems can be used in a broad range of applications.

How Does A Pneumatic System Work?

A pneumatic system needs five basic components to make, store, control, move, and use compressed air:

- A compressor—makes air.

- A reservoir (or receiver)—stores air.

- One or more valves—control air.

- A circuit—moves air between the other components.

- An actuator or motor—uses air to do something.

Pneumatic devices get all their power from the energy in the compressed air they use, so we can see that they need at least two key components: something to compress the air (the compressor) and something that uses compressed air to lift, move, or hold an object (the actuator). We also need a pipe or a network of pipes (the circuit) to get air from the compressor to the actuator and a component to switch the air on or off (a valve).

Since air is a very compressible gas, a basic system linking a compressor to an actuator through a circuit and a valve would work very slowly. When you switched it on, it would take time for the compressor to push air through the circuit and build up enough pressure to make the actuator move. So a pneumatic machine also has a reservoir where quite a bit of compressed air is stored under pressure, ready to deliver near-instant force as soon as the operating valve is opened.

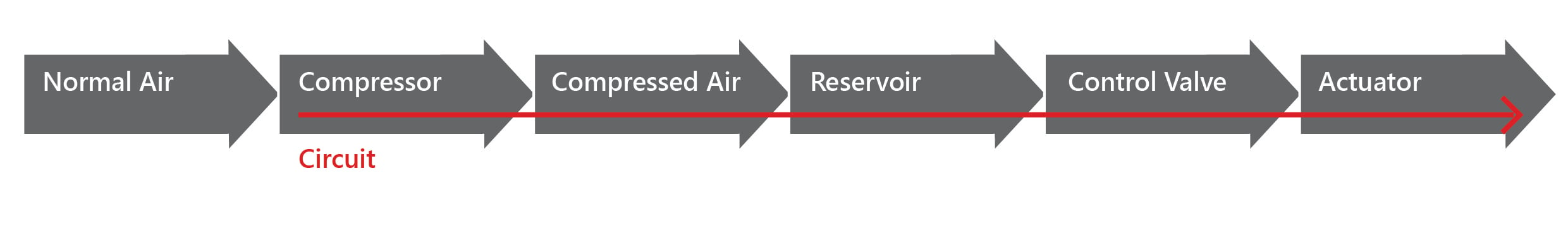

Overview: A Simple Pneumatic System

Overview: A Simple Pneumatic System

Where Can We Use Pneumatics?

As pneumatic components can perform three types of motions: Linear, swivel, and rotary, it is a versatile player in both the industrial systems and in everyday objects. Dental drills use pneumatic forces during checkups and cleanings, while pipe organs and player pianos use the compressed air to produce wonderful music.

In an industrial system, applications include packaging, filling, transfers of material, sorting of parts. stacking of components, stamping and embossing of components.

In majority of these applications, compressed air is used for one or more of the following functions:

- To determine the status of processors (sensors)

- Information processing (Processors)

- Switching of actuators by means of final control elements

- Carrying out work (actuators)

Thanks to technological progress made in material, design and production, processes have further improved the quality and diversity of pneumatic components and thereby contributed to their widely spread use in automation. Today, you can see pneumatic process automation being used in modern water technology, the chemical industry, the food and beverage industry, the pharmaceutical industry and many other segments.

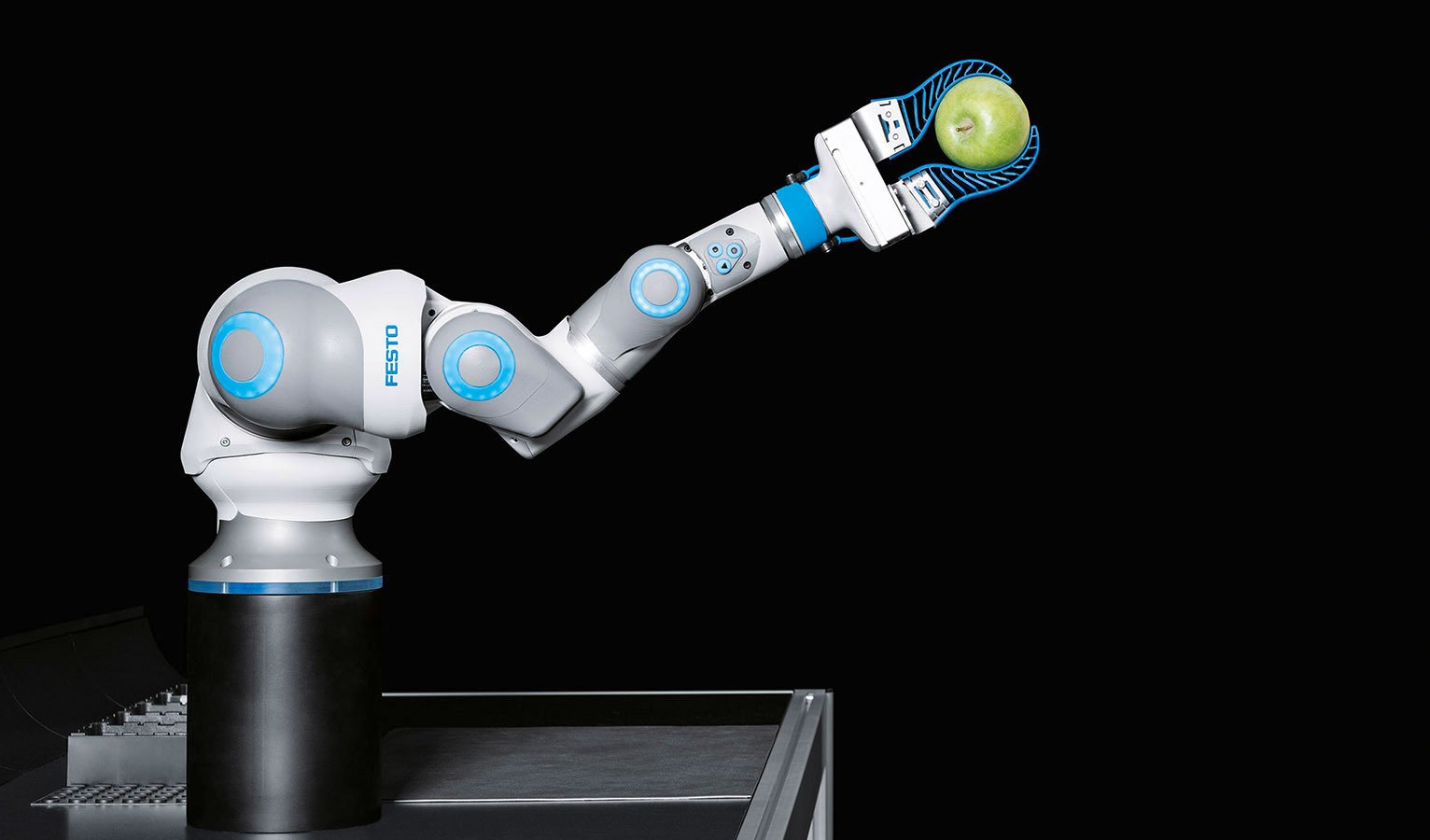

Innovation in pneumatic technology has also make waves for smart and creative designs in modern applications, such as the field of robotics to help with human tasks.

Pneumatic Technology: Whether free flexible movement or defined sequence,the modular design of pneumatic lightweight robot, BionicSoftArm can be used in numerous applications in human-robot collaboration.

Innovative Pneumatics: One of the innovative designs by the bionic team at Festo, the BionicFinWave is an autonomous underwater robot with unique fin drive, inspired by the undulating fin movement.

There You Have It!

We hope that you are able to have a better understanding on pneumatics, how pneumatic systems work and where they can be used. Please do subscribe to our blog if you would like to receive updates about pneumatics, its system and technology.

Interested to Learn More About Pneumatics?

Like to know how Pneumatic technology can help you in your operation? Get in touch with us below!

Festo is a global player and an independent family-owned company with its head- quarters in Esslingen am Neckar, Germany. The company has become the global market leader in its sector over the past 60 years thanks to its innovations and problem-solving competency, as well as a unique range of industrial training and vocational education programs. Festo supplies pneumatic and electric automation technology to 300,000 customers in the field of factory and process automation in over 35 industries.

Festo is a global player and an independent family-owned company with its head- quarters in Esslingen am Neckar, Germany. The company has become the global market leader in its sector over the past 60 years thanks to its innovations and problem-solving competency, as well as a unique range of industrial training and vocational education programs. Festo supplies pneumatic and electric automation technology to 300,000 customers in the field of factory and process automation in over 35 industries.