Bearings are manufactured with extreme precision. Therefore, it is necessary to pay strong attention to details to the mounting and maintenance process in order for the bearings to attain its best performance. Otherwise, it will lead to huge problems along the way, such as premature bearing failure and unplanned downtime, which is very costly to your business operation.

Poor fitting bearing is one of the common factors that can lead to premature failure, therefore steps should be taken in selecting bearing of a proper type and size. At this point, many would think that this step is enough to ensure a long bearing life and has overlooked another important "fitting" detail- shaft and housing fits; even with a properly selected bearing, it will still fail prematurely if the shaft and housing fits are incorrect.

Let's start with an introduction:

What is shaft alignment?

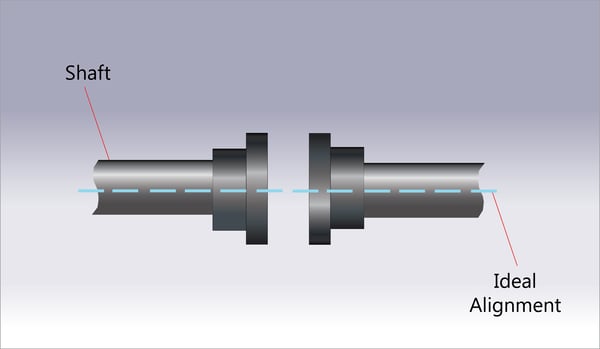

Shaft alignment is the process whereby two or more machines are positioned such that at the point of power transfers from one shaft to another, the axes of rotation of both shafts should be collinear when the machine is performed normally.

The illustration above shows the ideal shaft alignment whereby the the axes of rotation of both shafts are parallel.

Misalignment

Misalignment is one of the most common problem contributing to premature bearing seizure. Most rotating machinery often fall victim to misalignment and it can have an adverse effect on the life cycle of the machine.

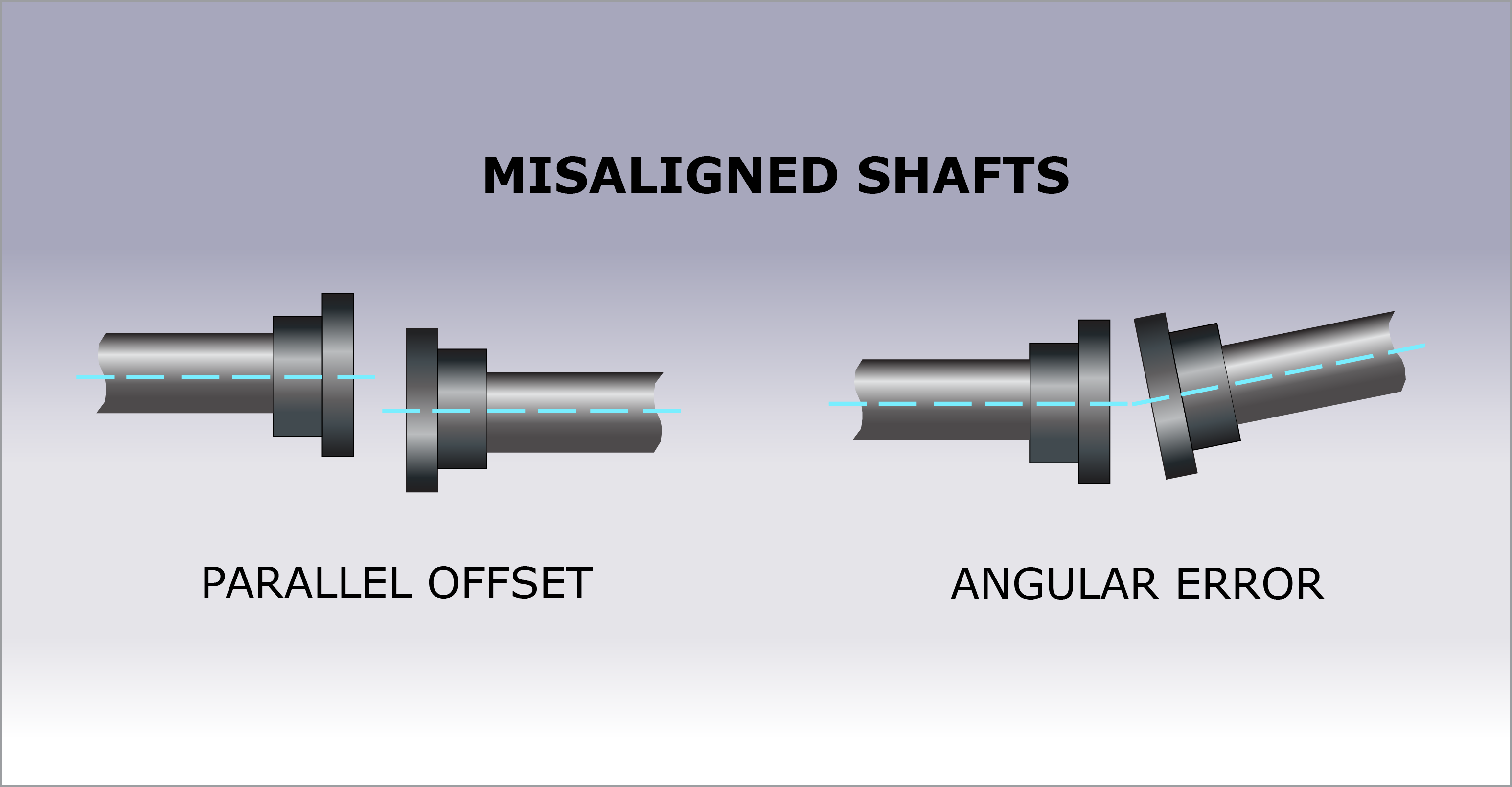

1. Shaft Misalignment

Misalignment of the shaft in relationship to the housing causes an overload of the balls or roller which result in failure.

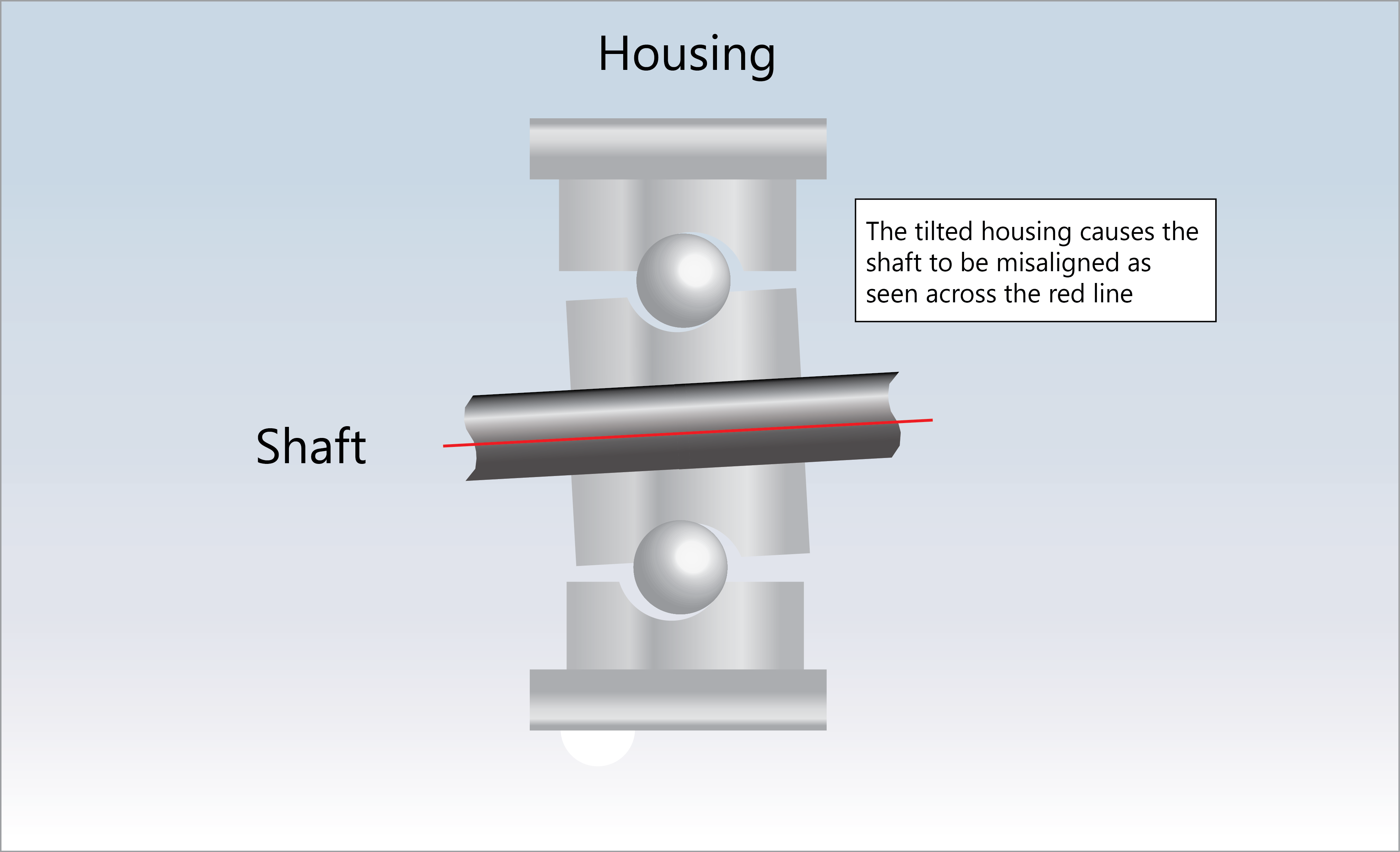

2. Housing Misalignment

Housing misalignment may be caused either by the housing being tilted in relation to the plane of the shaft. It could also be caused by the setting of housing frames or foundations.

Diagnose Misalignment

When the bearings are rotated over time, misalignment can generally cause a wear path on the inner and outer raceways of the bearing. It can be easily diagnosed by inspecting the rolling element path inside the bearing.

A well- aligned bearing will exhibit a running path down the center of the inner and outer rings, while a misaligned bearing will show uneven running paths.

Ways to Avoid Misalignment

One of the easiest way to avoid misalignment is to have a proper installation process. The shoulders of the shaft or housing contact the face of a bearing must be right angled to the shaft center line.

How to Recognize Misalignment?

Vibration analysis can be used to diagnose misalignment along with other mechanical defects. Laser alignment is another accurate method to detect misalignment.

Fit

Apart from alignment, another important factor when it comes to premature bearing failure is fitting.

Loose Fit

Although a loose fit eases the installation process, a fit that is too loose poses a problem as the bearing ring can potentially slip or "creep" onto the shaft or into the housing. Creep is the where relative slippage occurs between fitting surfaces and thereby creates a clearance between them surface. As a result, it can cause excessive wear and in the long run, lead to bearing failure.

Tight Fit

A slight press fit will generally help prevent creep, but too tight of a fit will eliminate the bearing internal clearance and cause a rise in operating temperature that can lead to premature failure.

A Proper Fit

Press fits will naturally make installation of the bearing more difficult and susceptible to damage, but with proper care, most problems can be avoided.

The type of fit is also determined by a few factors such as load, operating temperature, and shaft or housing material.

Temperature Conditions

In service, bearing rings normally reach a temperature which is higher than that of the components to which they are fitted. This can result in an easing of the fit of the inner ring on its seating, while outer ring expansion may prevent the desired axial displacement of the ring in its housing. Temperature differentials and direction of heat flow must therefore be carefully considered.

Load

Load decreases the interference of the inner ring. Hence, more interference would be required by heavier loads.

Housing and Shaft Materials

Different material strengths and thermal expansion rates make the proper fit different for each material. For example, aluminum expands more than steel. Therefore, an interference fit on an outer ring with an aluminum housing requires more interference than that of a steel housing. Furthermore, special conditions should be given to thin wall housings, hollow shafts, split housings and high vibration when making fit recommendations.

Feeling Overwhelmed?

We know, it is a lot of information to process, don't worry! Our team at SLSPRO are able to provide you with a free consultation to assist you with your needs.

Talk to us or book a consultation timeslot with our friendly engineers below.