The way a bearing is maintained and handled has a huge impact on its performance. Proper maintenance and handling leads to longer bearing life, minimized downtime, and greater productivity, which ultimately leads to cost savings and lower cost of ownership for your business. Here is a simple 8-point checklist for ensuring your bearing is always handled in the correct way and thus, optimizing performance.

1. Handle Bearings with Care

Bearings are precision components. As such, they should be handled and stored in a proper manner to avoid the entry of contaminants. Bearings should be stored horizontally in a clean and dry environment with their packaging intact. Care should be taken to avoid exposing bearings to airborne contaminants, as just a tiny speck of dirt in a raceway can cause premature bearing failure. Do not hammer, pound or apply direct force on a bearing or its outer ring. This can cause the rolling elements to be damaged and misaligned. Bearings should also not be installed if they have been dropped or mishandled, as little cracks and scratches can result in poor performance, and subsequently, premature bearing failure.

Do not remove bearings from their original packaging until ready to use, as they can be exposed to airborne contaminants like dust and dirt.

2. Inspect the Bearing Housing and Shaft

Before mounting a bearing, inspect the housing and shaft for physical condition or damage. Use a soft cloth to wipe the surfaces clean, and ensure any nicks and burrs are removed.

3. Apply the Correct Mounting Method

When mounting bearings, the correct method to use depends on the type of bearing and type of fit. Bearings with cylindrical bores are normally mounted through press fit method (mounting by pressing the bearing on the shafts) or shrink fit (heating the bearing to expand its diameter). Bearings with tapered bores can be mounted directly on tapered or cylindrical shafts with the help of tapered sleeves. Take note that pressure should only be applied with a press fit. Applying pressure without a press fit to the ring will damage the raceways.

Read More: Your Guide to Bearing Mounting- Methods & Tools

4. Prevent Direct Heating or Overheating

The maximum permitted temperature of bearings depends on the heat treatment of the material. Temperatures above the heat limit can permanently deform or soften the bearing steel, thus reducing load carrying capacity and leading to eventual failure.

Never heat a bearing using an open flame. Bearings should ideally be heated with induction heaters.

For more information on induction heaters, click here.

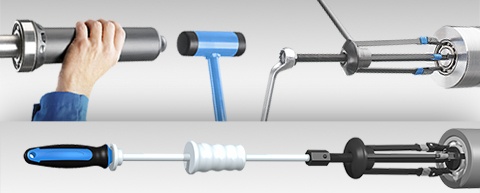

5. Use Proper Tools

Always use the appropriate equipment whenever handling bearings or during the mounting and dismounting process. Some of the specialized tools available for mounting and dismounting are bearing pullers, bearing fitting tool kits, oil injector kits, hydraulic nuts or induction heaters. These tools are customized to ensure a smooth mounting and dismounting process and minimise risk of bearing damage.

Avoid using general purpose tools for handling bearings. These are not specialized for bearings and may cause unwanted damage and incur unnecessary repair costs.

Download: Your Free 8-Point Bearing Maintenance Guide

The oil injection method and the SKF TMMK combi kit series are specialized for the quick and easy mounting of bearings.

6. Prevent Corrosion

If bearings are exposed to the presence of water over time, rust and corrosion may occur. This will cause premature bearing fatigue and over time, affect your machine performance and productivity, increasing operating costs.

When handling bearings, make sure you wear gloves, as perspiration on your hands, water, or other contaminants can cause corrosion. You may also use a water-resistant grease as your lubricant, which will then act as a protective barrier in damp environments.

For extremely corrosive environments, you might want to consider using bearings with different materials, such as ceramic bearings.

7. Proper Lubrication is Essential

Proper lubrication is extremely important if you want your bearings to have a prolonged life. Lubricants can be either oil or grease, and the right lubricant depends on a series of factors such as environmental conditions, temperature, speed and load. Follow your bearing manufacturer’s recommendations for the most suitable grade and type of lubricant. Failure to use the right lubricant can result in machine failure or voiding of warranty.

Do check lubrication levels frequently and be sure to change lubricants at least yearly.

8. Observe and Check for Danger Signs

The final step is to make sure you observe and be alert to any signs of abnormal or poor bearing performance. Examples include excessive noise, increased temperature or abnormal vibration. If your bearings display any of these signs, they should be monitored more closely, and if needed, removed before any further damage occurs to your equipment or machinery.

Vibration analysis can help you to track and detect any bearing danger signs early. Vibration analysis is part of condition monitoring, which can include technologies such as thermography, vibration analysis and oil analysis, tools which can help compare current bearing states with historical data and thus provide an accurate assessment of the remaining life of the bearing.

Proactive monitoring of your machinery can save your company a lot of unnecessary costs and expenses.

Read More: Failure Analysis Case Studies

Tools like vibration pens can also provide a quick, compact and easy option to check the condition of your rotating equipment. This can provide you with an early warning about potential machine problems before a costly breakdown or failure.

SKF Machine Condition Advisor CMAS 100-SL

SKF Machine Condition Advisor CMAS 100-SL

Interested in a free consultation with our experienced engineers?

We have a team of experienced engineers who are here to help you optimize your bearing performance. Book an appointment with us today.

SLS Pro provides a full range of integrated and specialized services, including bearing mounting and dismounting, lubrication management, vibration analysis and condition monitoring etc.

SLS Pro provides a full range of integrated and specialized services, including bearing mounting and dismounting, lubrication management, vibration analysis and condition monitoring etc.